Welcome to 3Design Co.

Welcome to the 3Design Co. Quality Management System (QMS) Manual. This document serves as the top-level guide to our commitment to quality, customer satisfaction, and continual improvement. It outlines the policies, processes, and controls we have implemented to ensure we consistently deliver exceptional design, engineering, and prototyping services. Our QMS is the backbone of our operations, providing a framework that empowers our team to innovate with confidence and precision.

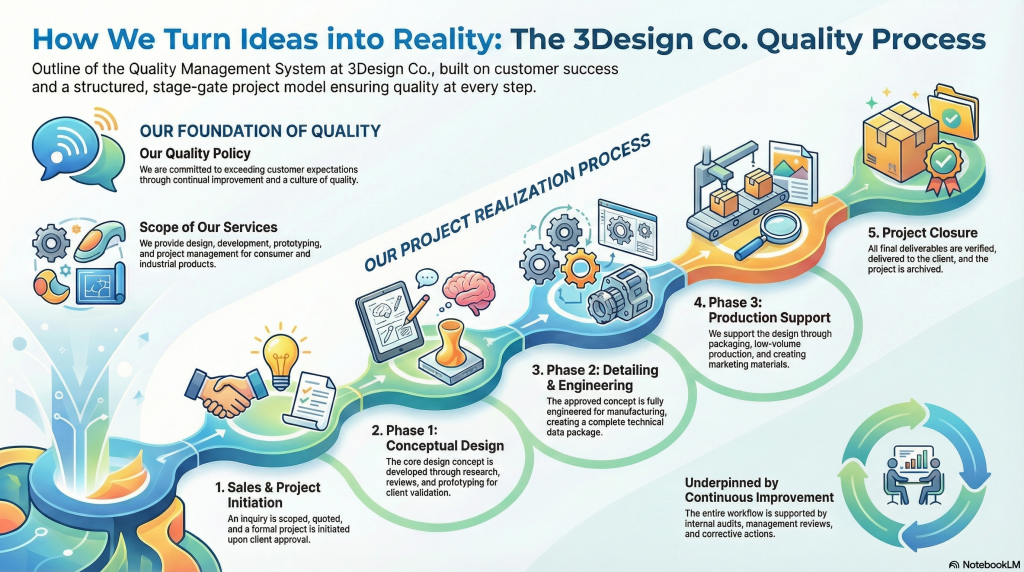

Quality Policy

The Senior Management Team has developed the following Quality Policy which governs day-to-day operations to ensure quality. The Quality Policy is communicated and implemented throughout the organization.

The Quality Policy of 3Design Co. is as follows:

3Design Co. is committed to transforming innovative ideas into reality through excellence in design and engineering. We strive to consistently meet or exceed customer expectations by adhering to a framework of continual improvement, fostering a culture of quality, and ensuring compliance with all applicable requirements. Our success is measured by the success of our clients.

Context of the 3Design Co. Organization

3Design Co. has reviewed and analyzed key aspects of itself and its stakeholders to determine the strategic direction of the company. This requires understanding the internal and external issues that are of concern to 3Design Co. and its interested parties. This exercise is formally conducted and documented per the procedure QP-410-01 – Context of the Organization.

Such issues are monitored and updated as appropriate, and are a key input into management reviews. This information is then used by senior management to determine the company’s strategic direction, which is defined in records of management review.

Scope of the 3Design Co. Quality Management System

Based on an analysis of the above issues of concern, interests of stakeholders, and in consideration of its products and services, 3Design Co. has determined the scope of the management system as follows:

The design, development, prototyping, and project management of consumer and industrial products for clients, including 3D printing, 3D scanning, and reverse engineering services.

The quality system applies to all processes, activities, and employees within the company. The facility is located at:

8801 Fast Park Dr. #301.

Raleigh NC 27612

Phone: (919) 771-3428

Web: www.3Designco.com

3Design Co. claims no exclusions from the ISO 9001:2015 standard.

QMS Processes and ISO 9001 Clause Application

3Design Co. has adopted a process approach for its management system. The table below identifies the top-level processes and maps them to the primary clauses of the ISO 9001:2015 standard they address. Each top-level process is defined in detail in its own procedure document.

| Process Name | Procedure No. | Primary ISO 9001 Clauses Addressed |

| Context, Risk & Opportunity Management | QP-410-01, QP-610-01 | 4 (Context), 5 (Leadership), 6 (Planning) |

| Project Realization | QP-751-01 | 8 (Operation), specifically: 8.1, 8.2, 8.3, 8.5, 8.6, 8.7 |

| Control of External Providers (Purchasing) | To be developed | 8.4 (Control of externally provided processes, products and services) |

| Performance Evaluation & Improvement | QP-920-01, QP-930-01, QP-1020-01 | 9 (Performance evaluation), 10 (Improvement) |

| Support Processes | QP-730-01 | 7 (Support), specifically: 7.5 (Documented Information) |

Appendix A: Overall Process Sequence & Interaction

The 3Design Co. QMS follows a Plan-Do-Check-Act cycle. The primary operational workflow is defined in the Project Realization Procedure (QP-751-01), which follows a customer-centric, stage-gate model:

- Sales & Project Initiation: An inquiry is received, scoped, and quoted. Upon approval, a formal Sales Order Review initiates the project.

- Phase 1 (Conceptual Design): The core design concept is developed through research, reviews, and prototyping. The phase concludes with customer validation.

- Phase 2 (Detailing & Engineering): The approved concept is engineered for manufacturing, creating a complete technical data package.

- Phase 3 (Post-Engineering & Production Support): The design is supported through packaging, low-volume production, and marketing material creation.

- Project Closure: All deliverables are verified and delivered, and the project is archived.

This entire operational flow is supported by the other key processes: Document Control, Internal Auditing, Management Review, and Corrective Action, which ensure the system is maintained and continually improved.

Appendix B: Subordinate QMS Procedures

- QP-410-01 – Context of the Organization

- QP-610-01 – Risk and Opportunity Management

- QP-730-01 – Control of Documents

- QP-751-01 – Project Realization (Design Control)

- QP-920-01 – Internal Audits

- QP-930-01 – Management Review

- QP-1020-01 – Corrective and Preventive Action

- (Additional procedures such as Purchasing, Control of Nonconforming Product, and Training will be developed as the QMS matures.)